7.13 Distribution centers

Distribution Center: a facility that performs consolidation, warehousing, packaging, decomposition, and other functions linked with handling freight. Orders are received, processed, and filled. Their main purpose is to provide value-added services to freight, which is stored for relatively short time periods (days or weeks). Goods stored in a distribution center have usually been sold and are in transit to their destination. They can also perform light manufacturing activities such as assembly and labeling.

Functions of a Distribution Center

Inventory Management: DCs store inventory to meet fluctuating demand. Centralized inventory allows for better control and optimization.

Order Fulfillment: DCs process incoming orders, picking, packing, and shipping products. Enables timely delivery, enhancing customer satisfaction.

Cost Reduction through Aggregation: Combining products from multiple sources for cost-effective transportation. Minimizes shipping expenses and maximizes economies of scale.

- Strategic Management for Distribution Centers

Network Optimization: Strategic placement of DCs for optimal geographic coverage. Reduces transportation costs, and enhances responsiveness.

Technology Integration: Implementing advanced technologies like automation and robotics. Increases efficiency, accuracy, and order processing speed.

Data-Driven Insights: Gathering and analyzing data on demand patterns, inventory turnover, and order processing times. Informed decision-making for inventory planning and customer service improvements.

Flexibility and Adaptability: Designing DCs to accommodate changes in demand and product assortment. Supports quick adjustments to market trends and customer preferences.

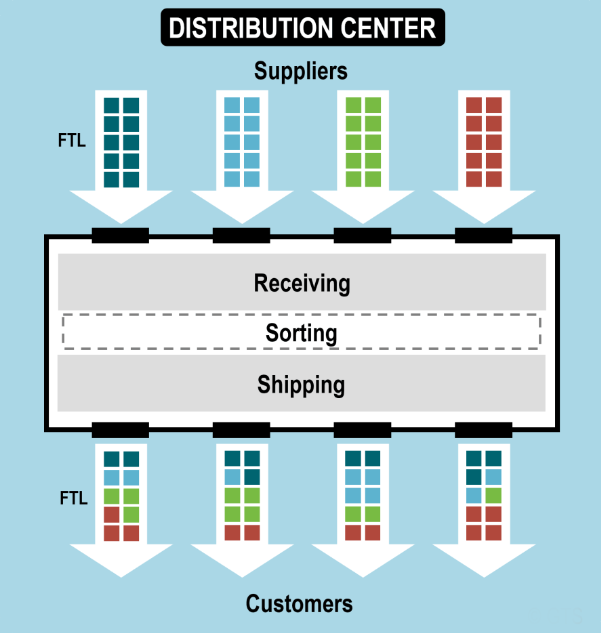

Figure 7.1: Distribution Center

Source: https://crashstats.nhtsa.dot.gov/Api/Public/ViewPublication/813375